Vaporization processes during cooling of miniature electronic devices

Abstract

The widespread introduction of new technologies contributes to the rapid development of various fields of technology, both in terms of increasing the functionality of systems and equipment and reducing the weight and size characteristics of individual components and devices in general. This is especially evident in radio electronics, particularly in computer technology, where the heat flux densities emitted by individual electronic components can be very high. In such a case, the temperature of the chips increases and may exceed the maximum permissible values. To ensure the specified operating temperatures of electronic equipment, the bubble boiling process is used. The highest intensity of heat transfer is observed during boiling. This is due to the evaporation of a thin microlayer of liquid under the growing steam bubble.

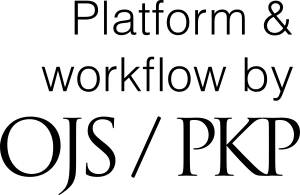

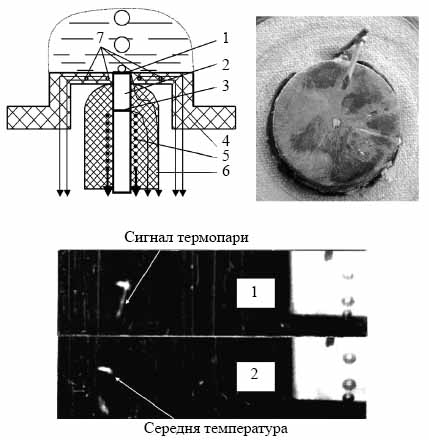

This paper describes an experimental study of the peculiarities of the bubble boiling process on small surfaces. The experiment’s unique feature was the visual observation of the combined appearance and growth of a steam bubble, as well as the temperature pulsation of the surface beneath it. The process of bubble boiling occurred in a large volume at atmospheric pressure on small copper surfaces with a diameter of 0.4 to 5.0 mm. The surface temperature was recorded using a specially designed thermocouple. The signal from the thermocouple was fed through an amplifier to a two-beam oscilloscope. Using a system of mirrors, the process of evolution of the vapour bubble and surface temperature fluctuations were recorded on the film of a high-speed movie camera. The film speed varied from 800 to 4000 frames per second.

Experimental results have shown that both spherical and hemispherical vapour bubbles grow on the surface during boiling. Moreover, the surface temperature fluctuation depends on the size of such bubbles at the moment of their detachment. The larger the bubble bursting diameter, the greater the amplitude of the surface temperature fluctuations. It is shown that the main factor in increasing the intensification of heat transfer is the evaporation of a microlayer of liquid under the vapour bubble. The dependence of the surface temperature fluctuation on the values of the detachable diameters of the steam bubbles is obtained.

Thus, if bubble-boiling cooling systems are used to maintain the temperature regime of electronic devices, it is necessary to take into account the temperature fluctuations of the heat transfer surface, as they can affect the operating characteristics of the devices.

References

Moore F. D., Mesler R. B. The measurement of rapid surface fluctuations during nucleate boiling of water, AIChE Journal, 1961, no. 7, iss. 5, рр. 620 – 624. https://doi.org/10.1002/aic.690070418

Rogers T.F., Mesler R.B. An experimental study of surface cooling by bubbles during nucleate boiling of water. AIChE Journal, 1964, vol. 10, iss. 5, pp. 656 – 660. https://doi.org/10.1002/aic.690100516.

Tolubinskiy V.I. Teploobmen pri kipenii [Heat exchange during boiling]. Kyiv: Nauk. Dumka, 1980. 316 p. (Rus)

Katto Y., Takahashi S., Yokoya S. Law of micro-liquid-layer formation between a growing bubble and a solid surface with a special reference to nucleate boiling. Bulletin of the JSME, 1973, vol. 16, iss. 97, pp. 1066 – 1074. https://doi.org/10.1299/jsme1958.16.1066

Jawurek H.H. Simultaneous determination of microlayer geometry and bubble growth in nucleate boiling. Int. Journal Heat and Mass Transfer, 1969, vol. 12, no. 8, pp. 843 – 848. https://doi.org/10.1016/0017-9310(69)90151-3

Cooper M.G. The microlayer and bubble growth in nucleate pool boiling. Int. Journal Heat and Mass Transfer, 1969, vol. 12, iss. 8, pp. 914 – 917. https://doi.org/10.1016/0017-9310(69)90155-0

Cooper M.G., Lloyd A.J.P. The microlayer in nucleate pool boiling. Int. Journal Heat and Mass Transfer, 1969, vol. 12, iss. 8, pp. 895 – 913. https://doi.org/10.1016/0017-9310(69)90154-9

Smirnov G.F. Calculation of the ‘initial’ thickness of the ‘microlayer’ during bubble boiling. J. Engng Phys., 1975, vol. 28, no. 3, pp. 369 – 374. https://doi.org/10.1007/BF00862021

Zhang Xi., El Mellas Is., Andreini N., Magnini M. The microlayer and force balance of bubbles growing on solid in nucleate boiling. International Journal of Multiphase Flow, 2025, vol. 183, 105049. https://doi.org/10.1016/j.ijmultiphaseflow.2024.105049

Zhang Xi., El Mellas Is., Magnini M. Predicting initial microlayer thickness in nucleate boiling using Landau – Levich theory. Journal of Fluid Mechanics, 2024, vol. 997, А44. http://dx.doi.org/10.1017/jfm.2024.559

Utaka Y., Kashiwabara Y., Ozaki M. Microlayer structure in nucleate boiling of water and ethanol at atmospheric pressure. International Journal of Heat and Mass Transfer, 2013, vol. 57, pp. 222 – 230. http://dx.doi.org/10.1016/j.ijheatmasstransfer.2012.10.031

Zhang X., Nikolayev V. S. Dewetting acceleration by evaporation. Journal of Fluid Mechanics, 2022, vol. 948, A49. https://doi.org/10.1017/jfm.2022.725

Urbano A., Tanguy S., Huber G., Colin C. Direct numerical simulation of nucleate boiling in micro-layer regime. International Journal of Heat and Mass Transfer, 2018, vol. 123, pp. 1128 – 1137. https://doi.org/10.1016/j.ijheatmasstransfer.2018.02.104

Kravets V.Yu. Heat transfer processes in miniature evaporation-condensation cooling systems. Kyiv: Interservice, 2023. 204 p. Available: https://ela.kpi.ua/handle/123456789/6711

Copyright (c) 2025 Vladimir Kravets, Vitaliy Chykalo, Yevhen Shevel

This work is licensed under a Creative Commons Attribution 4.0 International License.