Thermal analysis of cooling systems based on two-phase heat transfer devices

Abstract

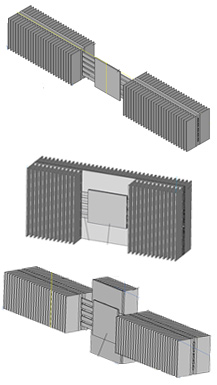

Lighting devices are critical tools for the emergency rescue operations at the dark as well for the other urgent actions directly in the area of emergency situations, since it is necessary to ensure a high level of illumination with constant intensity during the entire time of work. The current status of semiconductor technologies allows to create highly efficient high-power light sources, which allows to develop of a number of lighting systems based on LED sources (COB — chip-on-board — modules). But one of shortcoming of LED technology is a significant part of the electrical power is converted into the heat. So, such devices require special thermal management systems to ensure thermal requirements, which is determined primarily by the optical efficiency of COB modules and, accordingly, the total amount of electrical energy converted into heat. Today the heatsink based on passive two-phase heat transfer devices, such as heat pipes or vapor chambers, are widely used in the electronics and high-power LED lighting devices. In this case the thermal analysis of high-power LED lighting devices with such cooling systems at the early development stage is very important. So, in this work the thermal analysis of the three variants of high-power LED lighting device thermal management system with electrical power not less than 500 W was performed. The cooling systems designs based on aluminium heat sink with different two-phase heat transfer devices: heat pipes (copper powder heat pipes and aluminium grooved heat pipes), thermosyphons, pulsating heat pipes and vapor chamber were considered. The results of thermal simulation and their analysis of the above-mentioned cooling system variants options are shown in the paper. Based on thermal analysis of the cooling system design has been proposed and it has been shown that copper thermosyphons application with diameter 12 mm and with working fluid pentane in the aliminium heatsink increases its efficiency and ensures the heat dissipation at least 360 W by natural air convection into the environment at a maximum temperature of the LED COB module case of 100°C.

References

Yurtseven M.B., Mete S., Onaygil S. The effects of temperature and driving current on the key parameters of commercially available, high-power, white LEDs. Lighting Res. Technol., 2016, vol. 48, iss. 8, pp. 943 – 965. https://doi.org/10.1177/1477153515576785

Chang M.-H., Das D., Varde P.V., Pecht M. Light emitting diodes reliability review. Microelectron. Reliab., 2012, vol. 52, iss. 5, pp. 762 – 782. https://doi.org/10.1016/j.microrel.2011.07.063

Hamidnia M., Luo Y., Wang X.D. Application of micro/nano technology for thermal management of high power LED packaging — A review. Appl. Therm. Eng., 2018, vol. 145, рр. 637 – 651. https://doi.org/10.1016/j.applthermaleng.2018.09.078

Pryde J.R. Development of effective thermal management strategies for LED luminaries. Thesis. Loughborough University, UK, 2017. Available: https://dspace.lboro.ac.uk/2134/26687

Kayumov D., Bulatbaev F., Kayumova I. et al. An engineering approach for the qualitative assessment of the luminous flux of led lamps. Int. J. Energy Clean Environ., vol. 24, no. 1, pp. 31 – 43, 2023. https://doi.org/10.1615/InterJEnerCleanEnv.2022043776

Xiao C., Liao H., Wang Y. et al. A novel automated heat-pipe cooling device for high-power LEDs. Appl. Therm. Eng., vol. 111, pp. 1320 – 1329, 2017. https://doi.org/10.1016/j.applthermaleng.2016.10.041

Jouhara H., Chauhan A., Nannou T. et al. Heat pipe based systems — Advances and applications. Energy, 2017, vol. 128, pp. 729 – 754. https://doi.org/10.1016/j.energy.2017.04.028

Jouhara H., Reay D., McGlen R. et al. Heat Pipes: Theory, Design and Applications, Elsevier Ltd., 2024. https://doi.org/10.1016/C2019-0-04865-0

Heat pipe heat sink design. Celsia. Available: https://celsiainc.com/heat-sink-blog/heat-pipe-heat-sink-design/

Kozak D. V., Khairnasov S. M., Nikolaenko Yu. E. Experimental verification of a numerical model of the heatsink used in the cooling system for powerful LED light-ing devices. Proc. of the XXVІ ISPC “Modern information and electronic technologies”, Ukraine, Odesa, 2025, pp. 58 – 59. Available: https://www.old.tkea.com.ua/siet/archive/2025/MIET_2025_58.pdf

Pysʹmennyy Ye. M. et al. Potuzhnyy svitlodiodnyy osvitlyuvalʹnyy prystriy [Powerful LED lighting device]. Patent of Ukraine for a utility model No. 159438, 2025.

Copyright (c) 2025 Sergii Khairnasov, Dmytro Kozak

This work is licensed under a Creative Commons Attribution 4.0 International License.